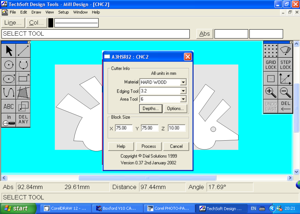

Search for jobs related to Boxford cad cam design tools serial or hire on the world's largest freelancing marketplace with 15m+ jobs. It's free to sign up and bid on. 10-JUL-2014: Mill arrived, mechanics and electrics work, has a 25W serial port. Be needed as the interlock prevents manual removal of chips during a program. For preparing a g-code file which can be loaded onto the CNC to cut a design. A license, installed on the Robotics CAD/CAM laptop) http://www.cambam.info/.

Separate post to avoid mixing this opinion with the fact work done by Toby and me. Why should we make changes to the Boxford? The first question I guess is whether it is useful as it is? The current setup is fine for learning, but of much less value to produce any finished article. Those using the machine have all learnt a massive amount, but still struggle to follow a basic design process from concept to finished product.

Limitations in the software nearly always result in compromises of the design to meet the limitations of the machine, OK for learning, but not for getting stuff made. So as is, it might remain a project or novelty, but not a tool for the space. In time, I think eventually it would be hard to justify the space taken compared to the value as a tool.

I think it important to understand, that CNC Milling is a complex process, a CNC Mill will never be an easy tool to use. Like other 3D CNC tools, we know that competency of 3D design technique and software is a prerequisite. Mythology edith hamilton pdf free download youtube. Also, knowledge of milling in general and appreciation of manual milling is required. Many hackspaces do not induct on CNC mills until users are trained on manual mills, this is usually true in industry too.

What I am saying is that if we make the Boxford easier to use, there is still a significant learning curve for new users. If we were to improve the VMC260, there will still be an entry learning level to usage (maybe 10 to 50 hrs), and so limited capability to make parts for casual users.

Based on my evaluation of the VMC260, which has a solid mechanical structure with CNC control, my opinion is that improvements can be made to turn the VMC260 into a productive tool, all be it that the entry level for users may be high. Costs of the improvements may be possible at around £100, but I think a figure of £500 is more realistic. Open to discussion here on group, or at rLab. I completely agree with all of that, Richard.

Adresnie tablichki v vektore. Provided by Scott Web Service LLC Scott Web Service of Wisconsin Statistics Report: sws-wis.com Summary Period: December 2016 - Referrer Generated 03-Jan-2017 00:17 EST. Adresnyie_Tablichki_V_ Vektore _AB755D.exe [磁力链接] 软件 创建时间: 2018-06-11 文件大小: 1.21 MB 文件数量: 1 下载热度: 711 最近下载: 1个月前 Adresnyie_Tablichki_V_ Vektore _AB755D.exe 1.21 MB.

In particular, I don't think that designing for or running a CNC mill will ever be a process that requires no experience, intuition or experimentation. It will never be the laser cutter, which for all intents and purposes is a printer/plotter. People should adjust their expectations and take that into account when considering the cost of options re the mill. Thus far on the Boxford, I've made some small brackets and adapters, nothing complicated, just some facing, pockets, channels and holes; maybe 4 or 5 tool changes. However, every time the Boxford software hung and didn't prompt for later tool changes. It's also not repeatable setting up datums, which would make swapping the vice a pain.

Whilst I think swapping the innards of the Boxford is doable I question the return on investment. The hardware is much more capable than the software to be sure, but how capable is it compared to £500 replacement hardware and professional control software? The software is critical, as demonstrated by the Boxford software. Alex showed me the de facto open source mill control software and frankly it looked like a teenager had thrown a UI toolkit at the screen. Complex processes don't require horrendous UX, in fact the inverse is true. We don't want to be in the same situation as with the Piranha where the software options are limited, so for me it's a priority that the replacememt is well known and can just plug in to Fusion or at least understand new/standard dxf or gcode.

As much as this is a hack space, it is also a maker space and I don't think the Boxford in any configuration will ever be a maker's machine. I don't see how I'd make more complicated projects on it than I already have. I also don't see how projects wouldn't require a great deal of time. Ian has done outstanding work downstairs where every tool just works if you have the skill, with no hackery or maze of accomodations to navigate.